2025/11/26

Huitong Xinda Permanent Magnet Variable Frequency Air Compressor: A New Benchmark in Innovative Energy Saving

【Enterprise Updates】Having been deeply engaged in the air compression equipment field for nearly a decade, Qingdao Huitong Xinda Air Compressor Co., Ltd. has closely followed the global wave of technological innovation. Relying on its profound insight into industrial gas demand, it has officially launched a new generation of permanent magnet variable frequency screw air compressor series. This series deeply integrates internationally cutting-edge two-stage compression, PLC intelligent control, and high-efficiency permanent magnet motor technologies. With core advantages of "over 50% energy-saving rate, full-scenario adaptation, and green low-carbon", it provides high-performance gas solutions for multiple industries such as machinery manufacturing, chemical industry, food and medicine, and transportation. Upon its launch, it has won bulk orders from more than 30 enterprises in Shandong, Jiangsu, Zhejiang and other regions, demonstrating the strong technical strength of local brands.

Driven by both the "dual-carbon" strategy and the transformation of Industry 4.0, high energy consumption costs, low operation and maintenance efficiency, and high pressure of environmental compliance have become core pain points restricting enterprise development. According to industry data statistics, the energy consumption of compressed air systems accounts for 10%-20% of the total industrial electricity consumption, while the energy waste of traditional fixed-frequency models under partial load conditions is as high as 30% or more. As a local enterprise focusing on energy-saving technology, the R&D team of Huitong Xinda has spent 2 years, deeply drawing on global innovation achievements of permanent magnet variable frequency air compressors, and optimizing and iterating by combining more than 1,200 sets of domestic industrial working condition data, to create this new generation of products that have both international technical standards and localized adaptability, perfectly solving the industry's pain points.

This series of products covers the full power range of 5-50 HP, with six core innovation highlights leading the industry upgrade:

1.Two-stage compression technology, energy efficiency reaches new heights: Adopting a vertical two-stage screw host design, the compression process is completed in stages. Compared with single-stage models, the gas production efficiency is increased by 15%, and compared with traditional fixed-frequency models, energy is saved by 30%-50%. Equipped with an IE4 ultra-high-efficiency rare earth permanent magnet synchronous motor, the motor efficiency is further improved by 15%-25% compared with the national standard first-class energy efficiency. The pressure loss is controlled within 0.02MPa, minimizing energy loss. Taking the 22 HP model as an example, running 8 hours a day can save more than 23,000 yuan in electricity bills every year, and the equipment investment can be recovered in as fast as 2 years.

1.Two-stage compression technology, energy efficiency reaches new heights: Adopting a vertical two-stage screw host design, the compression process is completed in stages. Compared with single-stage models, the gas production efficiency is increased by 15%, and compared with traditional fixed-frequency models, energy is saved by 30%-50%. Equipped with an IE4 ultra-high-efficiency rare earth permanent magnet synchronous motor, the motor efficiency is further improved by 15%-25% compared with the national standard first-class energy efficiency. The pressure loss is controlled within 0.02MPa, minimizing energy loss. Taking the 22 HP model as an example, running 8 hours a day can save more than 23,000 yuan in electricity bills every year, and the equipment investment can be recovered in as fast as 2 years.

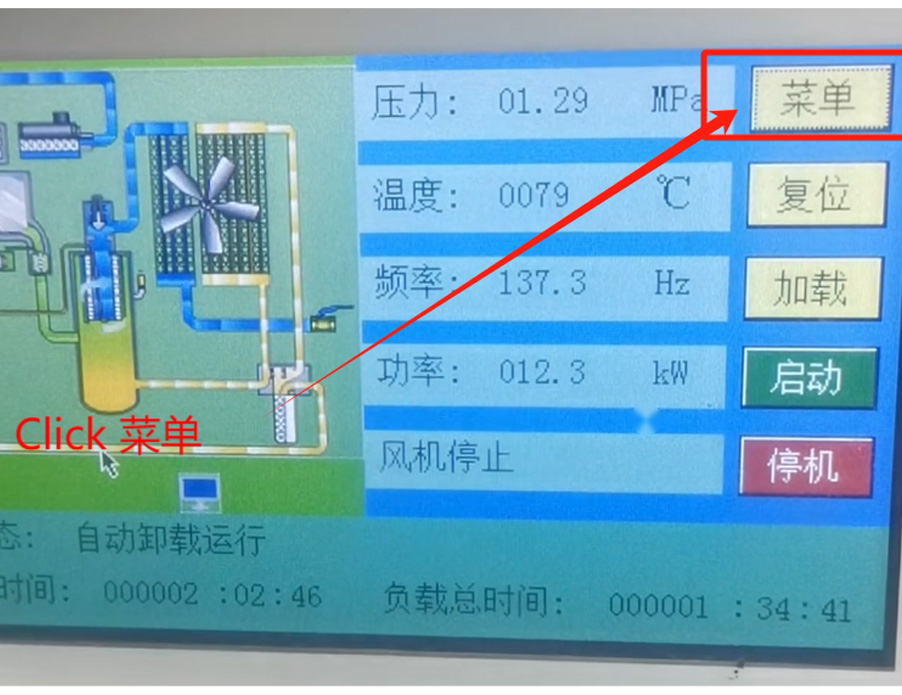

2.PLC intelligent control, precise and efficient operation and maintenance: Equipped with an industrial-grade PLC control system and integrated with high-precision sensors, it can collect more than 20 operating parameters in real time, such as speed, voltage, temperature, vibration, and energy consumption, which are intuitively displayed through the device's own 7-inch touch screen. The built-in intelligent algorithm can automatically analyze the operating data and early warn of potential faults such as oil circuit blockage and pressure abnormalities, reducing unplanned downtime by more than 30%. It supports automatic start-stop and load adaptive adjustment, avoids motor start-up impact, extends the service life of the equipment, with MTBF (Mean Time Between Failures) exceeding 10,000 hours. The operation is simple and easy to learn, without the need for professional operation and maintenance personnel.

3.Efficient air-cooled design, stable adaptation to multiple working conditions: The innovative and optimized air-cooled heat dissipation system improves heat dissipation efficiency by 20% through scientific planning of air circulation paths and upgrading the structure of heat dissipation fins. Even under complex working conditions such as high-temperature workshops and long-term high-load operation, it can quickly dissipate the heat of the equipment, ensuring that the motor and host are always at a suitable working temperature, avoiding performance degradation or failures caused by overheating, and greatly improving the operating stability and durability of the equipment in diverse industrial scenarios.

3.Efficient air-cooled design, stable adaptation to multiple working conditions: The innovative and optimized air-cooled heat dissipation system improves heat dissipation efficiency by 20% through scientific planning of air circulation paths and upgrading the structure of heat dissipation fins. Even under complex working conditions such as high-temperature workshops and long-term high-load operation, it can quickly dissipate the heat of the equipment, ensuring that the motor and host are always at a suitable working temperature, avoiding performance degradation or failures caused by overheating, and greatly improving the operating stability and durability of the equipment in diverse industrial scenarios.

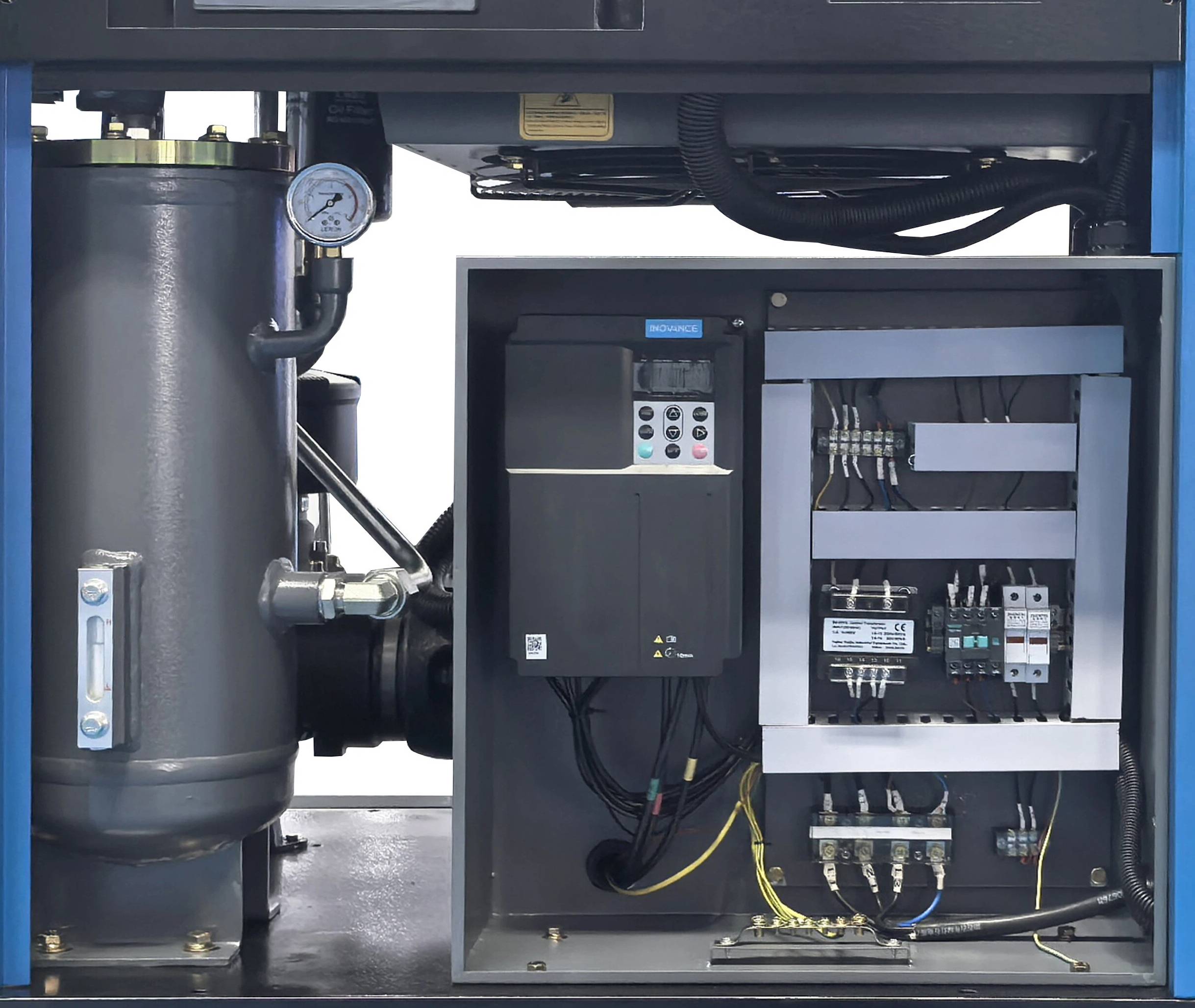

4.Integrated compact structure, doubling space utilization: Continuing Huitong Xinda's classic integrated design, it highly integrates the two-stage screw host, permanent magnet motor, frequency converter, air storage tank and precision filtration system. The floor area is reduced by 40% compared with traditional split-type models, which is especially suitable for small and medium-sized enterprises with tight factory space. The quick-detachable panel design allows the maintenance of core components without professional tools, and daily maintenance can be completed by one person, reducing operation and maintenance costs by 50%.

5.Precise pressure control, adapting to multiple scenarios: Equipped with an imported frequency converter, the pressure fluctuation is precisely controlled within ±0.01MPa, perfectly meeting the processes with strict requirements on gas source stability such as laser cutting and precision welding. The optimized body structure and noise reduction design significantly reduce the operating noise compared with traditional models, eliminating the need for a separate soundproof machine room, creating a more comfortable working environment for workshop operators, and adapting to various industrial production scenarios.

6.Low-oil environmental protection attributes, in line with new environmental protection regulations: Adopting efficient oil-gas separation technology and imported filter elements, the oil-gas separation efficiency reaches 99.99%, and the oil content is strictly controlled within 3ppm, achieving low-oil clean gas supply, reducing the risk of oil pollution from the source. It can not only meet the environmental protection requirements of conventional industries such as machinery manufacturing and chemical industry, but also adapt to fields such as food and medicine that have high standards for gas source cleanliness. The intelligent eco-mode can automatically adjust the operating status according to gas demand, further reducing carbon emissions, helping enterprises easily comply with strict environmental protection regulations and build green factories.

6.Low-oil environmental protection attributes, in line with new environmental protection regulations: Adopting efficient oil-gas separation technology and imported filter elements, the oil-gas separation efficiency reaches 99.99%, and the oil content is strictly controlled within 3ppm, achieving low-oil clean gas supply, reducing the risk of oil pollution from the source. It can not only meet the environmental protection requirements of conventional industries such as machinery manufacturing and chemical industry, but also adapt to fields such as food and medicine that have high standards for gas source cleanliness. The intelligent eco-mode can automatically adjust the operating status according to gas demand, further reducing carbon emissions, helping enterprises easily comply with strict environmental protection regulations and build green factories.

"The global technological trends of permanent magnet variable frequency air compressors focus on energy conservation, intelligence, and greenization. Huitong Xinda's new-generation products are an accurate response to this trend," said Guo Yanling, general manager of Huitong Xinda. "We have always been customer demand-oriented, deeply integrating international cutting-edge technologies with local working conditions, and through continuous innovation, we provide enterprises with full-cycle gas supply solutions for 'cost reduction, quality improvement, and compliance', helping the industrial sector achieve carbon emission reduction goals."

Currently, Huitong Xinda's new-generation permanent magnet variable frequency air compressor series has been fully mass-produced and supplied. The company has simultaneously launched three exclusive services: free on-site survey and customized gas supply solutions, 24-hour rapid maintenance response (arrival within 4 hours in Qingdao area), and 3-year free warranty for core components. Corporate customers can view detailed technical parameters through the company's official website (https://www.qdhtxd.com), call the service hotline 400-0053-338 for quotation consultation, or make an appointment to visit the Jimo production base (No. 2 Nanquan Yida Road, Lancun Town, Jimo District, Qingdao) to observe the equipment operation effect on site.

As an air compression equipment service provider deeply rooted in the local market and with a global layout, since its establishment in 2017, Huitong Xinda's products have been exported to 12 countries including South Korea, the United States, and Russia, serving more than 1,200 domestic industrial enterprises. The launch of this new-generation permanent magnet variable frequency air compressor not only improves the company's energy-saving product matrix, but also demonstrates the core strength of local brands in connecting with international technologies and empowering China's intelligent manufacturing, injecting strong impetus into the green transformation of more enterprises.